-

Kitchen Knives

-

Bernal Cutlery House & Collaborations

- Greenfield Series

- Bernal Cutlery Black Label

- INVICTUS - K Sabatier | Butcher's Guide

- Nouvel Ideal - K Sabatier

- GS+ Ko Sabaki - Konosuke

- Small Chef - Rolin Knives

- Stainless Clad - Tosa Tadayoshi

- Knife Rolls - ILE

- Pizza Cutter - F+W | Prince

- Sakai Style - Blenheim Forge

- Sori Series - Sakai Kikumori

- Kurouchi - Nakagawa | Sakai Kikumori

- Shop by Use

- Shop by Shape

- Shop by Category

-

Shop by Maker

- Ashi Hamono

- Astral Works

- Au Nain

- Au Sabot

- AZ Knives

- Bernal Cutlery Manufactory

- Blenheim Forge

- Chazeau Honore

- Eichenlaub

- Florentine Kitchen Knives

- Friedr. Herder

- Gihei Knives

- Goyon-Chazaeu

- HADO

- Hatsukokoro

- Hitohira

- J Adams

- John Nowill & Sons

- K Sabatier

- Kaji Bei

- Kanehide

- Kenji Togashi

- Kogetsu

- Konosuke

- MAC Knife

- Masakane

- Morihei

- Mutsumi Hinoura

- Myojin Naohito

- Néron

- Naozumi

- Nigara Hamono

- Pallares

- Roland Lannier

- Rolin Knives

- Sakai Kikumori

- Satoshi Nakagawa

- Seki Kanetsugu

- Tagai Sanjo

- Tanabe Tatara

- Tosa Tadayoshi

- Tosa Tsukasa

- Tsukasa Hinoura

- Wakui

- Yoshikane

- Knife Storage

- Sayas & Guards

- Knife Care

- Trade In

- Bargain Bin

-

Bernal Cutlery House & Collaborations

- Knives & Tools

- Sharpening

-

Kitchen Tools

-

Shop by Brand

- Ambrogio Sanelli

- Andre Verdier

- Ateco

- Au Nain

- Chefs Press

- Due Buoi

- Dexter Russell

- F. Dick

- Geo Yukio Hattori

- Gestura

- Hardmill

- Hitohira

- Inside Line Equipment (ILE)

- Jones Cutting Boards

- Kagetsu Donabe

- KYOTOH Donabe

- Kuramoto

- Lancaster

- Lundy Way

- MAC Knife

- Made In

- Netherton Foundry

- Noda Horo

- Nordic Ware

- Pallares

- Peugeot

- Prince

- Silky

- SILPAT

- Shop by Use

- Cookware by Material

- Cookware by Type

- Prep Tools

- Cutting Boards

- Utensils

- House & Kitchen Scissors

- Softgoods

- Chef's Press

- Cleaning Supplies

-

Shop by Brand

- Tableware

- Vintage

- Pantry

- Books & Gifts

- Services & Info

or

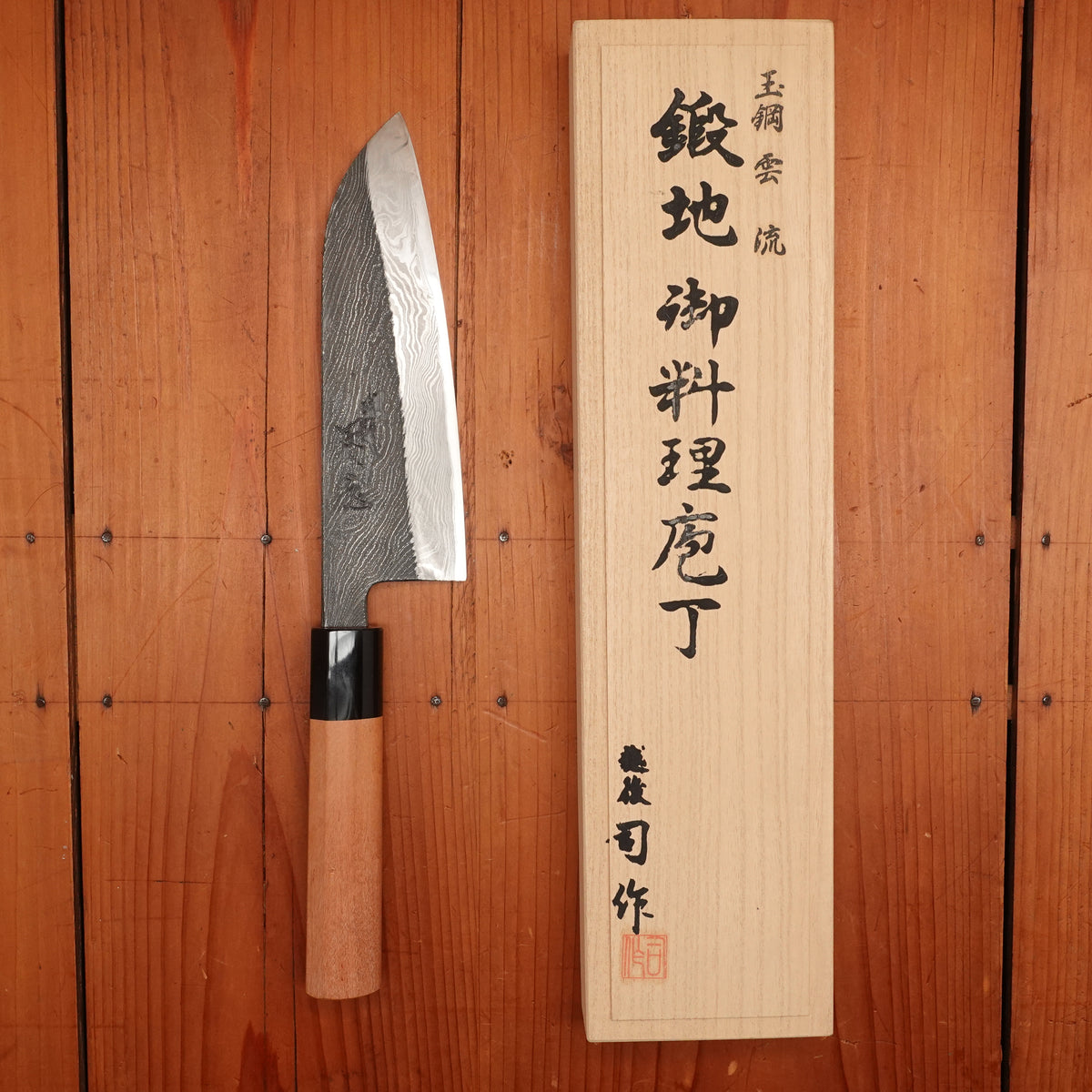

Tanabe Tatara Tsukasa Hinoura 170mm Santoku Tamahagane Suminagashi Sakura / Horn

-

Regular Price

-

£3,853.72

-

Sale Price

-

£3,853.72

-

Regular Price

-

Sale

Sold Out

-

Unit Price

- /per

- Regular Price

- £3,853.72

- Sale Price

- £3,853.72

- Regular Price

- Unit Price

- /per

We are very honored to be able to offer a limited series of knives made with hand made tamahagane steel made as a collaboration between blacksmith Tsukasa Hinoura and the Tanabe family.

The Tanabe family begins in 1460. In 2016, the 25th generation Tabe Chouemon revitalized the family's Tatara production. Tanabe Family's sacred fire that is burned continuously to be used at each operation was started with flames provided by Izumo Taisha, the oldest and arguably the most important Shinto shrine in Japan. The Tanabe family now conducts 2 Tatara operations a year, creating the ancient tamahagane steel and now combining it with modern design and features collaboration with renowned Japanese blacksmiths.

By some standards, the old tamahagane steel has long been eclipsed by more modern industrial steels as tamahagane cannot boast the same carbon content, much less the efficiency of industrial steels but its importance to Japanese blacksmithing cannot be overstated. There would be no Japanese sword making, tool making or knife making traditions as we know them without tamahagane and for this reason it is regarded with such reverence. The fact that the Izumo Taisha temple's fire was used to rekindle the the fire at Tanabe Tatara emphasizes the spiritual significance of Tamahagane.

Tsukasa Hinoura is a third generation knife maker in Sanjo, Niigata, Japan. Hinoura-San uses no modern machinery in the production of his knives, and he does all the finish grinding and sharpening himself. From the forging of the jigane cladding, the warikomi forge lamination of the steel core and cladding, the water quench heat treatment to the final whetstone finish and all steps in between, traditional techniques are methodically employed. Hinoura-San is known for his examination of traditional Japanese blacksmithing with modern metallurgical microscopy, on both his own work and the work of other Japanese blacksmiths. All of his research supported the functional importance of traditional techniques that had been started to be viewed as antiquated or unnecessary with modern steels and as a result, Hinoura-san's steel quality is superb.

Hinoura-san was a student of the immensely skilled Kosuke Iwasaki who is responsible for Sanjo blacksmithing enjoying the high level of skill it does today and for the spirit of generosity with sharing techniques and technical information about traditional blacksmithing in the Japanese blacksmithing world and beyond. The number of Japanese blacksmiths especially in Sanjo that are well known and respected today who trace their craft lineage through Iwasaki is enormous.

Tsukasa Hinoura's output is very limited due to the high degree of labor in each knife made, we are very happy to get them whenever they are available, and made with this rare steel it is even more so.

Please note that these specifications and photos are frequently updated to represent the most current stock available.

Brand: Tanabe Tatara

Smith

Smith: Tsukasa Hinoura

Producing Area: Sanjo, Niigata, Japan

Profile: Santoku

Size: 170mm

Steel Type: Carbon

Steel: Tamahagane

Handle: Ho Wood & Buffalo Horn Ferrule

Total Length: 310mm

Handle Length: 127mm

Handle to Tip Length: 184mm

Blade Height: 51mm

Edge Length: 169mm

Thickness: 3.49mm

Weight: 180g

Hand Orientation: Ambidextrous

This is a carbon steel knife. Carbon steel is expected to develop a dark patina with use. It needs to be hand washed and dried immediately after use. Do not air dry. Do not put it in the dishwasher. Long exposure to moisture and debris will result in rust. Any rust development should be removed with a light abrasive.

Twisting, scraping, and heavy use, as well as use on hard and very dense objects can lead to edge damage. Use on a quality wooden cutting board will help the knife stay sharper for longer. Use on hard surfaces like plates and bamboo will reduce the edge life and can result in edge damage.

We recommend hand sharpening on whetstones. We have found that most Japanese knives perform best at a finer finish starting around 4000. Avoid pull through sharpeners and non-water cooled mechanized sharpening. Ceramic honing rods are preferred.

Recently Viewed

About Bernal Cutlery

We are a full-service cutlery shop offering sharpening services, Japanese and Western culinary knives, vintage knives, outdoor, pocket and craft knives, cooking tools and accessories. We also offer knife skills and sharpening classes, and more.

We are proud to serve kitchen professionals, knife enthusiasts and home cooks alike. Located in the Mission District of San Francisco, California.

766 Valencia Street, SF, CA 94110

1 Ferry Building, Ste. 26, SF, CA 94110