Hitohira Togashi 300mm Yanagi Shirogami 2 D Ho / Horn with Saya

-

Regular Price

-

£211.34

-

Sale Price

-

£211.34

-

Regular Price

-

Sold Out

-

Unit Price

- per

- Regular Price

- £211.34

- Sale Price

- £211.34

- Regular Price

- Unit Price

- per

Hand made in Sakai, iron clad shirogami #1 forged by dentoukougeishi master smith Kenji Togashi and expertly ground by his son Kenya. Shirogami 1 has both great edge formation and a longer lived edge life than the more commonly found shirogami 2. Togashi-san is famous for his shirogami 1 for good reason.

The tachi finish refers to tachi-togi finish scratches running from tip to tang, as the knife is cleaned with a light abrasive in the future it will blend into the existing scratch pattern.

Listed Length: 240mm

Total Length: 449mm

Edge Length: 291mm

Heel Height: 35mm

Spine Thickness: 4mm

Weight:

Orientation: Right-handed

Blade Type: Carbon Steel

Steel Type: Shirogami 2 (White Paper #2)

Steel Hardness (HRC):

Maintenance: More Attention

Handle Type: Japanese (wa)

Handle Material: Ho (Magnolia) & Horn Ferrule

Dive Deeper

Fine - Single Bevel

Sharpening Supplies

Stones & Accessories selected specifically for this knife.

Bernal Cutlery Takarazukushi 500 Grit Soft & Fast Ceramic Japanese Whetstone

- Regular Price

- £34.47

- Sale Price

- £34.47

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 4000 Grit Yellow Semi-Hard Resinoid Japanese Whetstone

- Regular Price

- £61.45

- Sale Price

- £61.45

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 1200 Grit Blue Marble Semi-Soft Ceramic Japanese Whetstone

- Regular Price

- £55.46

- Sale Price

- £55.46

- Regular Price

-

- Unit Price

- per

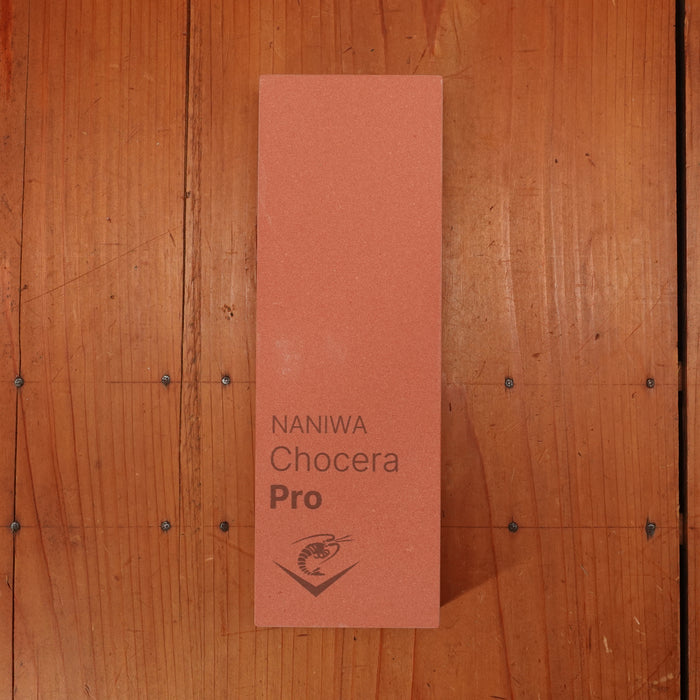

Naniwa Chosera Pro 800 Whetstone

- Regular Price

- £50.96

- Sale Price

- £50.96

- Regular Price

-

- Unit Price

- per

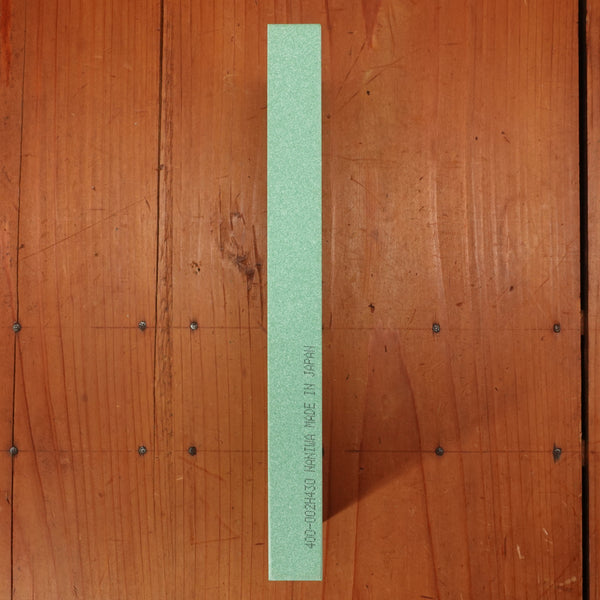

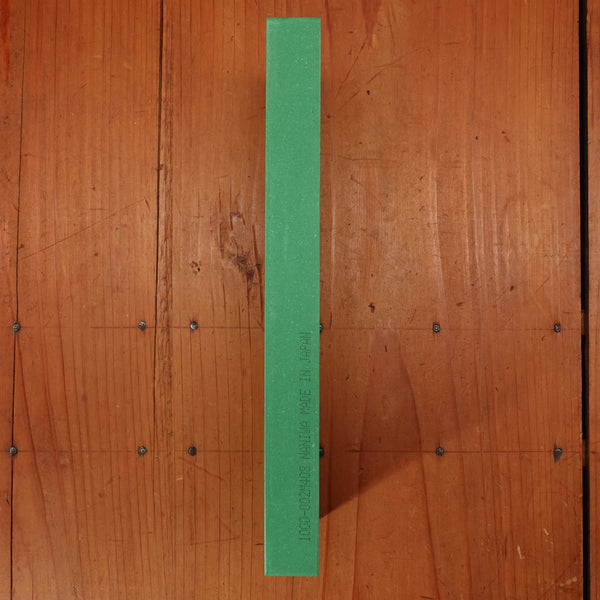

Naniwa Chosera Pro 400 Whetstone

- Regular Price

- £47.96

- Sale Price

- £47.96

- Regular Price

-

- Unit Price

- per

Naniwa Chosera Pro 1000 Whetstone

- Regular Price

- £58.45

- Sale Price

- £58.45

- Regular Price

-

- Unit Price

- per

Naniwa Chosera Pro 2000 Whetstone

- Regular Price

- £64.45

- Sale Price

- £64.45

- Regular Price

-

- Unit Price

- per

Naniwa Chosera Pro 5000 Whetstone

- Regular Price

- £115.41

- Sale Price

- £115.41

- Regular Price

-

- Unit Price

- per

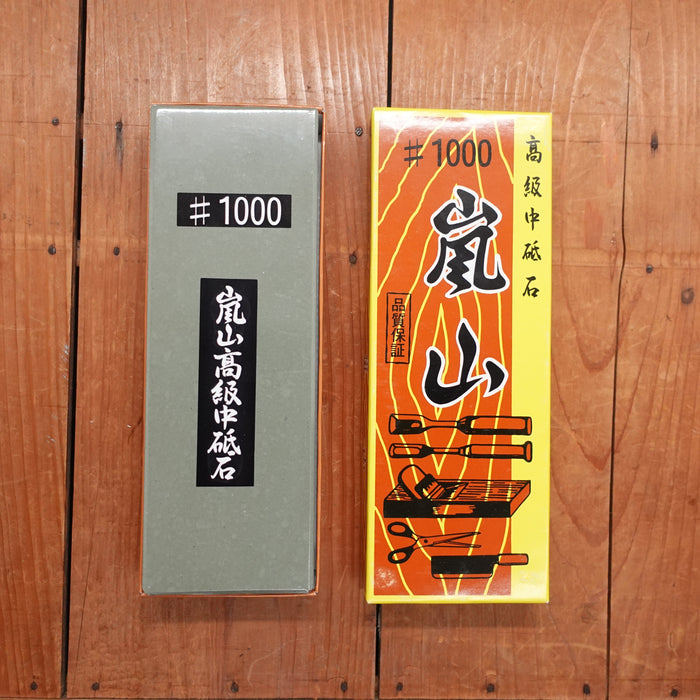

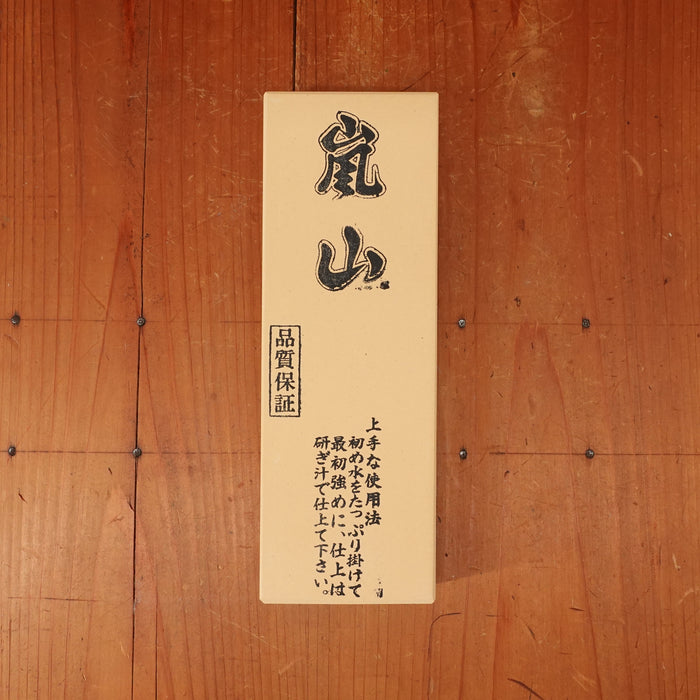

Arashiyama #1000 Whetstone Medium Hard with Natural Grit

- Regular Price

- £31.48

- Sale Price

- £31.48

- Regular Price

-

- Unit Price

- per

Arashiyama #6000 Whetstone Stone NO Wooden Base

- Regular Price

- £43.47

- Sale Price

- £43.47

- Regular Price

-

- Unit Price

- per

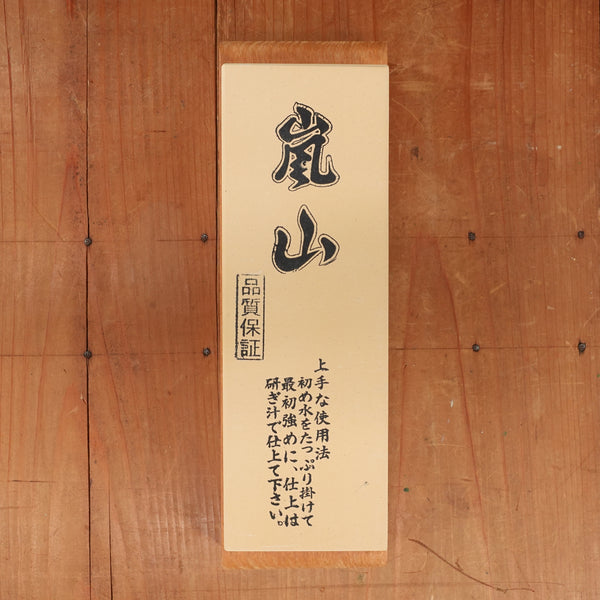

Arashiyama #6000 Whetstone With Nagura Stone and Wooden Base

- Regular Price

- £46.46

- Sale Price

- £46.46

- Regular Price

-

- Unit Price

- per

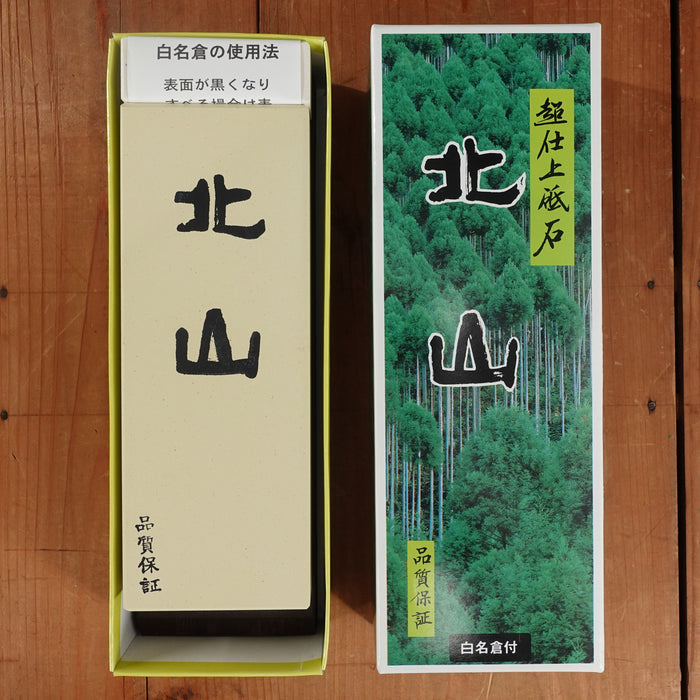

Kitayama #8000 Whetstone with Nagura and Wooden Base

- Regular Price

- £62.95

- Sale Price

- £62.95

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Chromium Oxide Precharged Deburring Strop

- Regular Price

- £26.23

- Sale Price

- £26.23

- Regular Price

-

- Unit Price

- per

Atoma #140 Diamond Stone No Holder

- Regular Price

- £78.69

- Sale Price

- £78.69

- Regular Price

-

- Unit Price

- per

Shirogami 2 (White Paper #2)