Another wide range of stones to choose from. Coarser stones are best for fast, flat edge setting and geometry repair, medium for standard maintenance edge setting and fine for finish work. We recommend working on the micro bevel to set a new edge first, then follow up on the wide bevels or wide single bevel to preserve the ideal blade geometry and apply your desired finish. Always follow up on a strop with chromium oxide to remove burr.

Note, a ceramic rod is acceptable on double bevel knives for a quick on the go touch up but is not good for single bevel as it will remove the flatness of the inside ‘flat’ hollow ground ura edge.

Bernal Cutlery Takarazukushi 1000/4000 Combination Grit Japanese Whetstone

- Regular Price

- £61.38

- Sale Price

- £61.38

- Regular Price

-

- Unit Price

- per

Chromium Oxide Deburring Compound - 50ml

- Regular Price

- £14.97

- Sale Price

- £14.97

- Regular Price

-

- Unit Price

- per

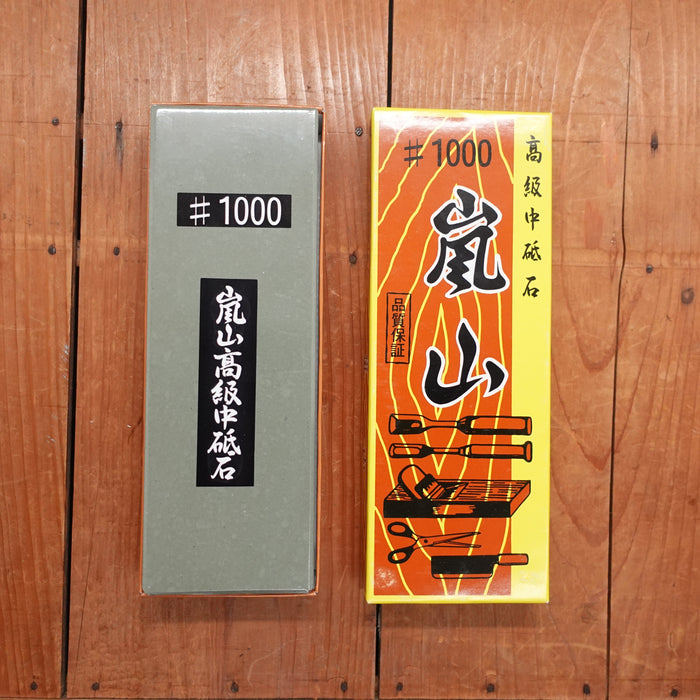

Arashiyama #1000 Whetstone Medium Hard with Natural Grit

- Regular Price

- £31.44

- Sale Price

- £31.44

- Regular Price

-

- Unit Price

- per

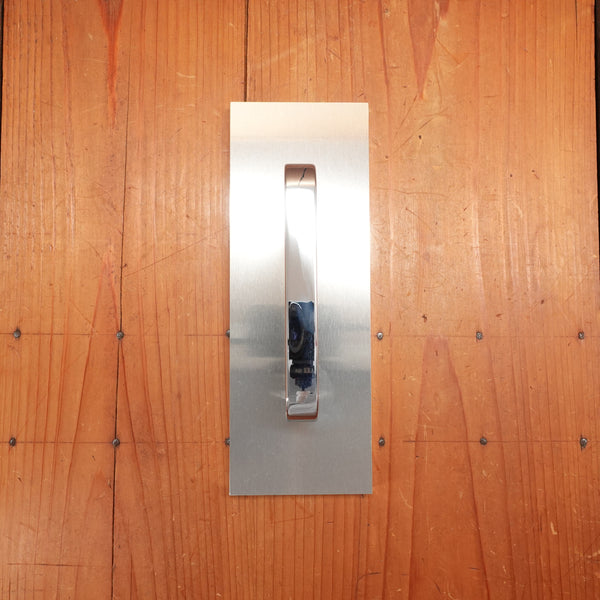

Atoma #140 Diamond Stone With Handle

- Regular Price

- £97.32

- Sale Price

- £97.32

- Regular Price

-

- Unit Price

- per

Atoma #140 Diamond Stone with Holder

- Regular Price

- £95.82

- Sale Price

- £95.82

- Regular Price

-

- Unit Price

- per

Morihei Hishiboshi Hi Whetstone 500 Grit

- Regular Price

- £48.66

- Sale Price

- £48.66

- Regular Price

-

- Unit Price

- per

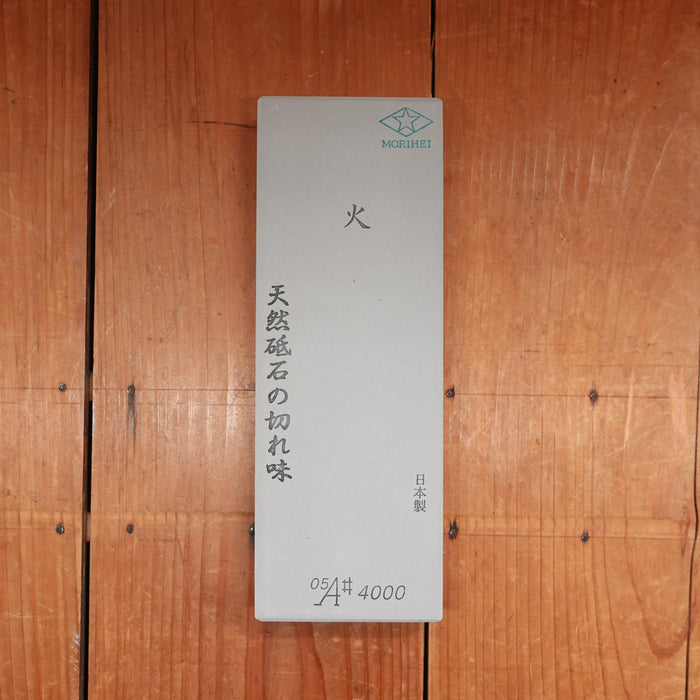

Morihei Hishiboshi Hi Whetstone 4000 Grit

- Regular Price

- £63.63

- Sale Price

- £63.63

- Regular Price

-

- Unit Price

- per

Morihei Hishiboshi Fine Nagura

- Regular Price

- £14.97

- Sale Price

- £14.97

- Regular Price

-

- Unit Price

- per

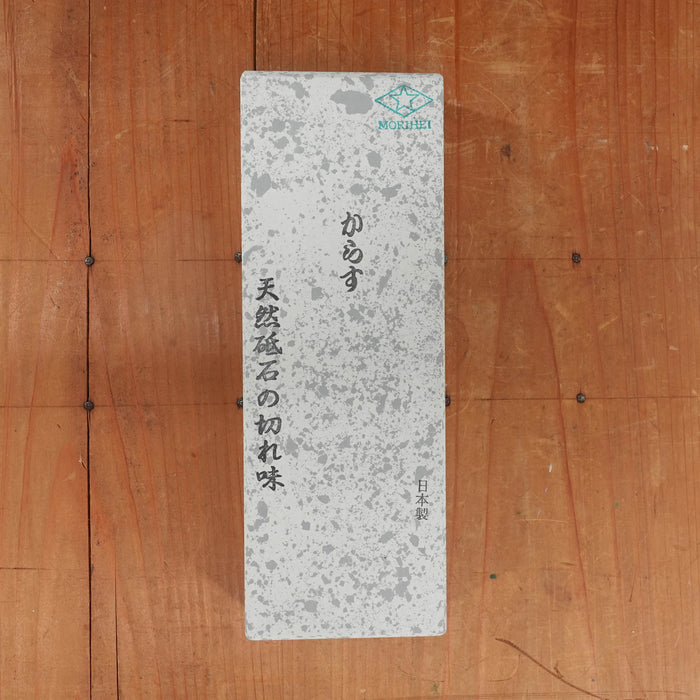

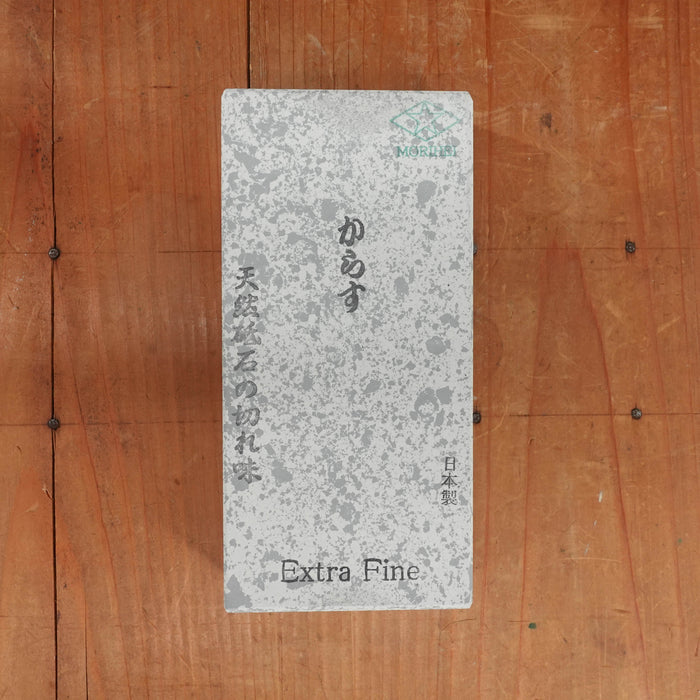

Morihei Hishiboshi 9000 Grit Karasu Whetstone

- Regular Price

- £59.89

- Sale Price

- £59.89

- Regular Price

-

- Unit Price

- per

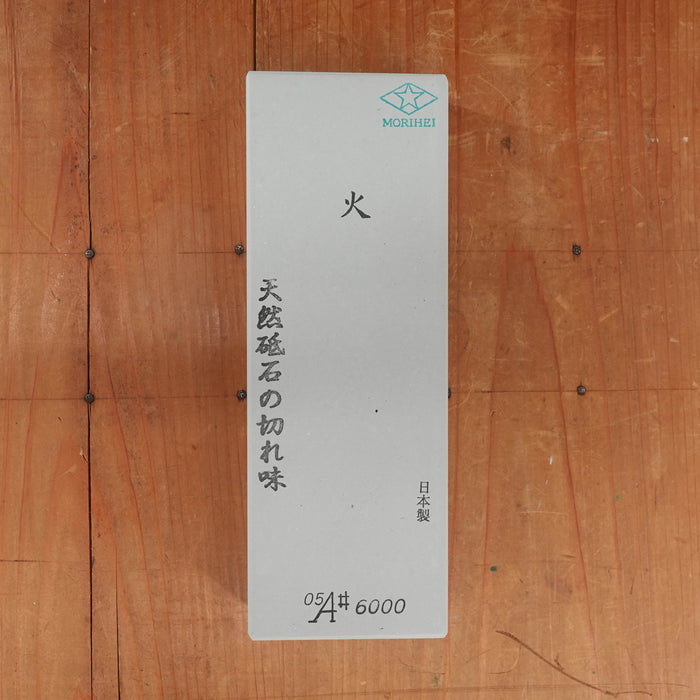

Morihei Hishiboshi Hi Whetstone 6000 Grit

- Regular Price

- £59.89

- Sale Price

- £59.89

- Regular Price

-

- Unit Price

- per

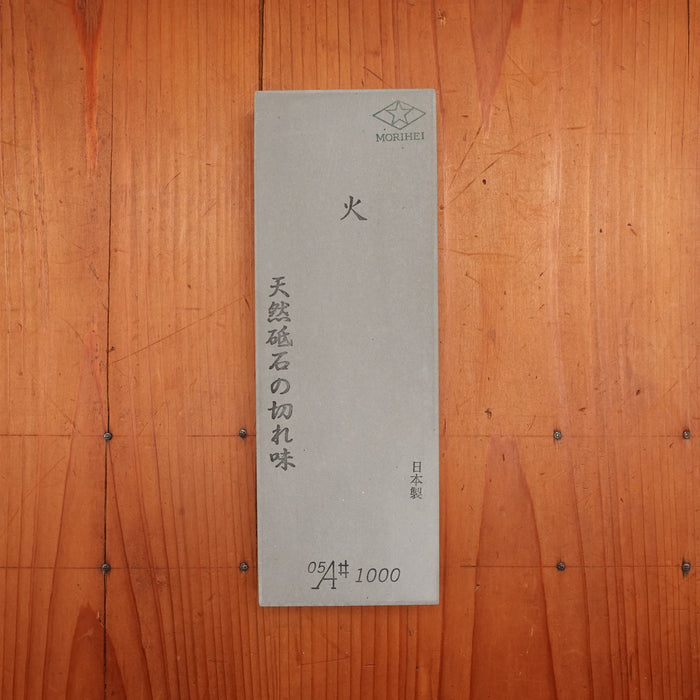

Morihei Hishiboshi Hi Whetstone 1000 Grit

- Regular Price

- £44.91

- Sale Price

- £44.91

- Regular Price

-

- Unit Price

- per

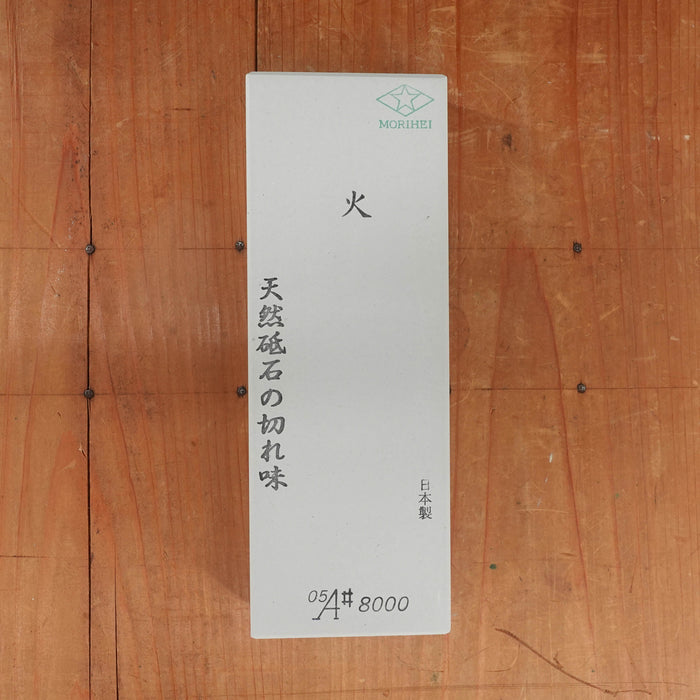

Morihei Hishiboshi Hi Whetstone 8000 Grit

- Regular Price

- £78.60

- Sale Price

- £78.60

- Regular Price

-

- Unit Price

- per

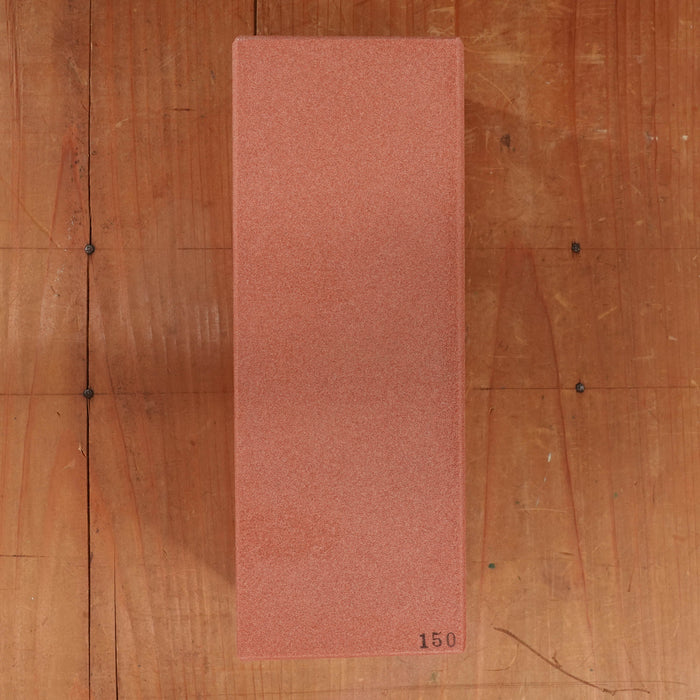

Hitohira Orange Whetstone 150

- Regular Price

- £44.91

- Sale Price

- £44.91

- Regular Price

-

- Unit Price

- per

Morihei Hishiboshi 12000 Grit Karasu RAZOR Whetstone

- Regular Price

- £93.57

- Sale Price

- £93.57

- Regular Price

-

- Unit Price

- per

Tanaka Toishi Whetstone #10,000 Blue Hard

- Regular Price

- £67.37

- Sale Price

- £67.37

- Regular Price

-

- Unit Price

- per