Konosuke Sanjo GS+ 240mm Gyuto SLD Migaki Khii Chestnut Handle with Leather Sheath

-

Regular Price

-

$347.00

-

Sale Price

-

$347.00

-

Regular Price

-

Sold Out

-

Unit Price

- per

- Regular Price

- $347.00

- Sale Price

- $347.00

- Regular Price

- Unit Price

- per

Konosuke GS+ Thin light hamaguri convex ground SLD steel core with stainless cladding with octagonal chestnut wood octagon handle and leather sheath.

Konosuke GS+ series knives are a thin convex ground three layer san mai forged blade with a stainless cladding and a semi-stainless/stainless SLD core with a chestnut handle. SLD steel is an improved SKD11 steel most commonly used in tap and die tools and metal stamping dies. It is designed to stay tough when treated hard and to retain its workability at a high hardness as well. For knife making this translates to a very long lived tough edge with near stainless or stainless properties; it holds an edge well and even cuts well as it dulls.

Listed Length: 240mm

Total Length: 390mm

Edge Length: 236mm

Heel Height: 50mm

Spine Thickness: 1.92mm

Weight:

Orientation: Ambidextrous

Blade Type: Semi-Stainless Steel

Steel Type: SLD

Steel Hardness (HRC): 61-62

Maintenance: Some Attention

Handle Type: Japanese (wa)

Handle Material: Khii (Chestnut) Laurel

Dive Deeper

Medium-Fine finish - Japanese

Sharpening Supplies

Stones & Accessories selected specifically for this knife.

Arato-kun #220 Extra Coarse Grit Whetstone

- Regular Price

- $34.00

- Sale Price

- $34.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 1200 Grit Blue Marble Semi-Soft Ceramic Japanese Whetstone

- Regular Price

- $74.00

- Sale Price

- $74.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 4000 Grit Yellow Semi-Hard Resinoid Japanese Whetstone

- Regular Price

- $82.00

- Sale Price

- $82.00

- Regular Price

-

- Unit Price

- per

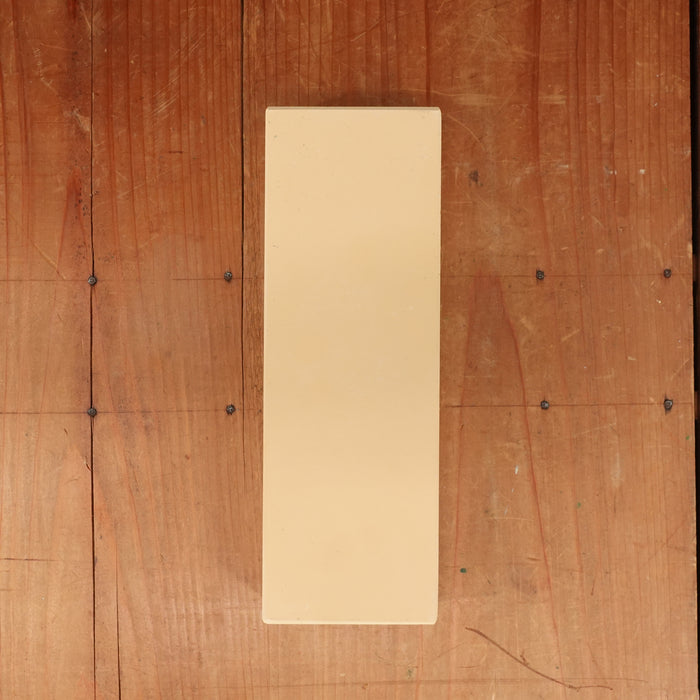

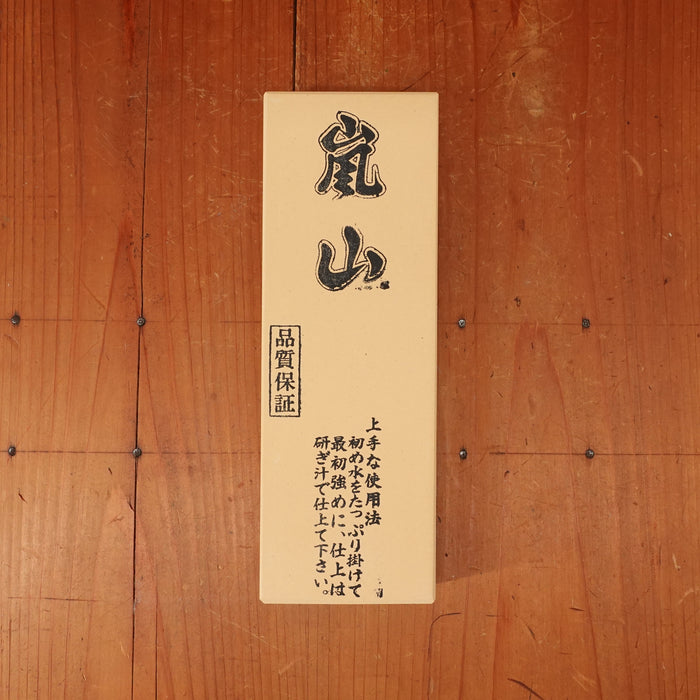

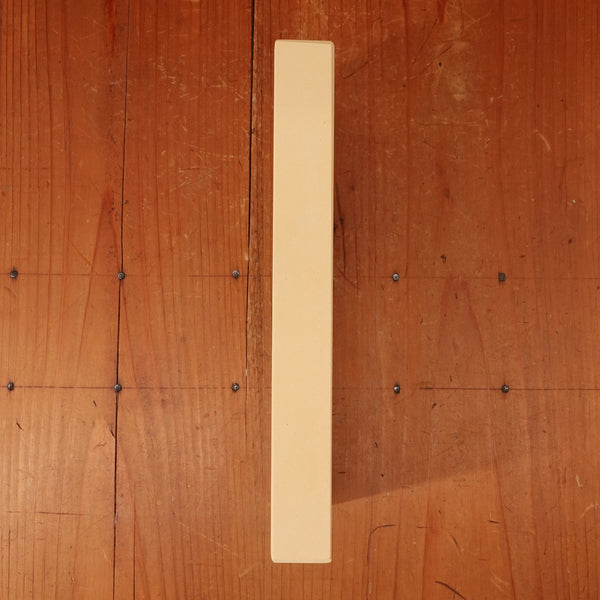

Arashiyama #6000 Whetstone Stone NO Wooden Base

- Regular Price

- $58.00

- Sale Price

- $58.00

- Regular Price

-

- Unit Price

- per

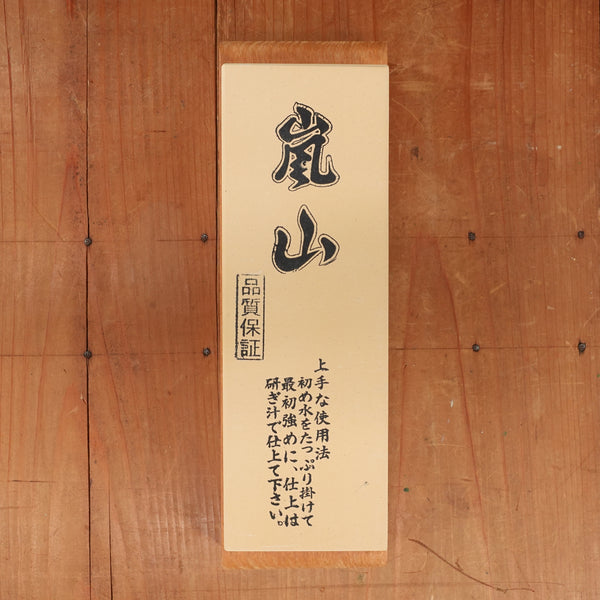

Arashiyama #6000 Whetstone With Nagura Stone and Wooden Base

- Regular Price

- $62.00

- Sale Price

- $62.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Monodiachrome™ Precharged Deburring Strop

- Regular Price

- $40.00

- Sale Price

- $40.00

- Regular Price

-

- Unit Price

- per

SLD