Sakai Kikumori Nakagawa x BC 240mm Gyuto Shirogami 1 Kurouchi Ho Wood with Saya

-

Regular Price

-

$439.00

-

Sale Price

-

$439.00

-

Regular Price

-

Sold Out

-

Unit Price

- per

- Regular Price

- $439.00

- Sale Price

- $439.00

- Regular Price

- Unit Price

- per

We are proud to introduce as the sole North American retailer, knives done as a collaboration between Sakai Kikumori and Nakagawa Hamono. Inspired by a conversation with Bernal Cutlery’s Lisa and Josh with Sakai Kikumori, Kawamura-san at Kikumori asked what we would like to see, and shirogami 1 and aogami 1 kurouchi gyutos from Nakagawa Hamono came to mind.

These knives represent a blend of the rustic and the refined. They have a dark forge-scale kurouchi finish and exceptionally thin grinds to support the superb forging. Nakagawa-san's smithing is characterized by thorough heat treatment with excellent heat control during forging. The result are knives that have remarkable edge formation and edge retention while remaining tough.

Shirogami is rated at 1-3; increasing in carbon content as the number gets smaller. Typically, shirogami 3 is tough with a shorter edge life than shirogami 2, and shirogami 1 has the best edge life with the least toughness. However, in the hands of Nakagawa-san, this shirogami 1 is given better toughness which offsets its more brittle nature. This is definitely a sharpener's steel that works well at a very fine finish. It is a real pleasure to sharpen Nakagawa-san's shirogami 1. It has a longer lived edge than his shirogami 2 and performs well at very fine finishes. It’s a true blank slate that’s great for a huge variety of finishing stones, especially natural stones.

These have a natural (as opposed to chemically applied) kurouchi finish which will include some hammer marks and rougher cosmetic grinder marks. When cared for properly, the kurouchi will gradually fade and be replaced with a patina from use.

Sakai Kikumori was started in 1926 and draws on Sakai's 600 year history as the major center of traditional Japanese cutlery manufacturing. They work with a large variety of Sakai's best smiths, sharpeners and small factories to offer a wide variety of knives ranging from traditional to modern.

Listed Length: 240mm

Total Length: 374mm

Edge Length: 227mm

Heel Height: 50mm

Spine Thickness: 3.10mm

Weight:

Orientation: Ambidextrous

Blade Type: Iron Clad Carbon

Steel Type: Shirogami 1 (White Paper #1)

Steel Hardness (HRC): 63-64

Maintenance: More Attention

Handle Type: Japanese (wa)

Handle Material: Ho (Magnolia) & Horn Ferrule

Dive Deeper

Medium-Fine finish - Japanese

Sharpening Supplies

Stones & Accessories selected specifically for this knife.

Arato-kun #220 Extra Coarse Grit Whetstone

- Regular Price

- $34.00

- Sale Price

- $34.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 1200 Grit Blue Marble Semi-Soft Ceramic Japanese Whetstone

- Regular Price

- $74.00

- Sale Price

- $74.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Takarazukushi 4000 Grit Yellow Semi-Hard Resinoid Japanese Whetstone

- Regular Price

- $82.00

- Sale Price

- $82.00

- Regular Price

-

- Unit Price

- per

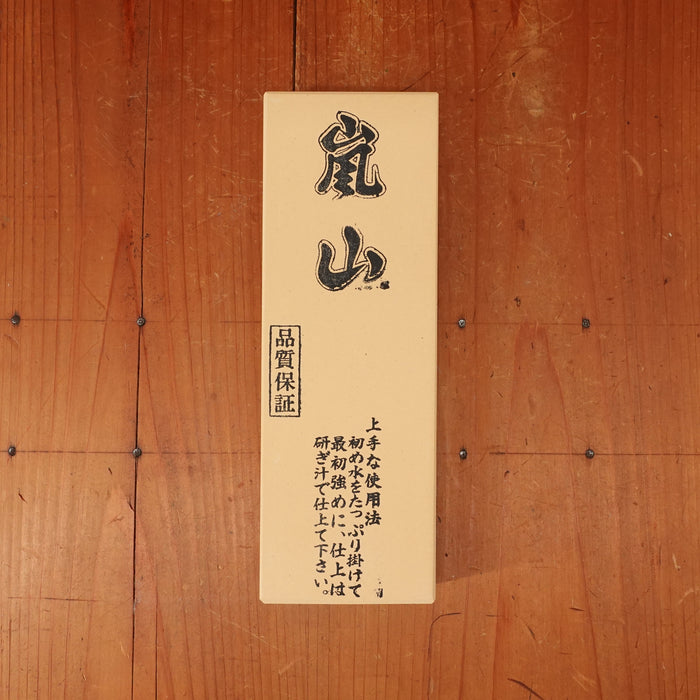

Arashiyama #6000 Whetstone Stone NO Wooden Base

- Regular Price

- $58.00

- Sale Price

- $58.00

- Regular Price

-

- Unit Price

- per

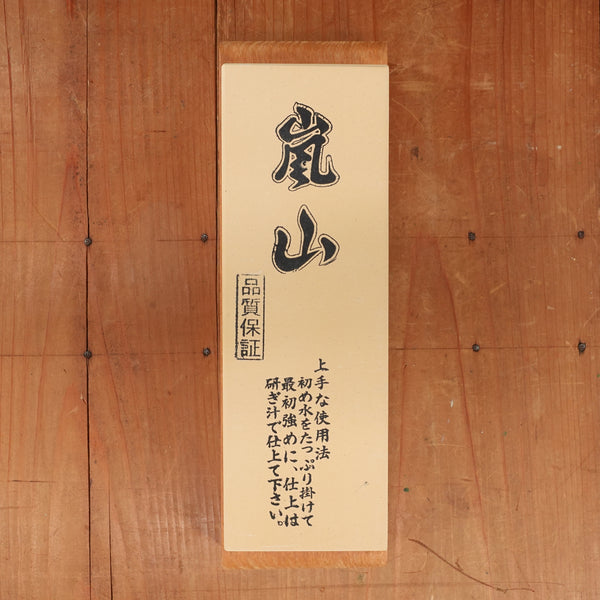

Arashiyama #6000 Whetstone With Nagura Stone and Wooden Base

- Regular Price

- $62.00

- Sale Price

- $62.00

- Regular Price

-

- Unit Price

- per

Bernal Cutlery Monodiachrome™ Precharged Deburring Strop

- Regular Price

- $40.00

- Sale Price

- $40.00

- Regular Price

-

- Unit Price

- per

Shirogami 1 (White Paper #1)