-

Currency

-

NEW

- All New Products

- New Kitchen Knives

- New Kitchen Tools

- Latest Vintage

- New Pocket & Outdoor

- New Pantry

-

What's in my Basket Series

- Nite Yun - Lunette

- Scott & Frost Clark - Dad's Luncheonette, Chef & Author

- Angela Wilson - Avedano's

- Susan Kim - Eat Doshi

- Seth Stowaway - Osito

- Dr. Harold McGee - Author

- Ryo Sakai -Kuma Sushi

- Ian McNemar - Woodworker, Instructor

- Anna Voloshyna - Author

- Jorge Martinex Lillard - Lolo´

- Chris Yang - Piglet & Co

- Griffin Wilson - @cabincorn

- Gabe Rudolph - Gestura Utensils

- Molly DeCoudreaux - Food Photographer

- Geoff Davis - Burdell Soul Food

- Jen and Wes - @crazythickasians

- Josh Donald - Bernal Cutlery

- Kelly Kozak - Bernal Cutlery

- Jessica Sullivan - Poppy SF

- Sylvan Mishima Brackett - Rintaro

- Michael Myers - Film Character

- Ali Hooke - @alihooke

- Bruce Hill - The Chef's Press

- Dylan Carasco - Butcher's Guide

- Spencer Horowitz - Hadeem

-

Japanese Knives

- Ashi Hamono

- Gihei Knives

- Godo Tadaharu

- Hatsukokoro

- Hitohira

- Iwasaki Kamisori

- Kaji-Bei

- Kamo Shiro

- Kanehide

- Konosuke

- MAC Knife

- Masakane

- Makoto Tadokoro Marushin

- Morihei

- Myojin Riki Sesakusho

- Nakagawa Hamono

- Naozumi

- Nigara Hamono

- Sakai Kikumori

- Shigefusa

- Tagai

- Takada no Hamono

- Tanabe Tatara

- Tosa

- Tsukasa Hinoura

- Yoshikane

- Yoshikazu Tanaka

- Wakui

-

Global Knives

- Allday Goods (GBR)

- Alma Knife Co. (USA)

- Astral Works (USA)

- Au Sabot (FRA)

- AZ Knives (ARG)

- Benchmade Cutlery (USA)

- Bernal Cutlery (USA)

- Blenheim Forge (GBR)

- Chazeau Honoré (FRA)

- Dexter Russell (USA)

- Eichenlaub Tableware (DEU)

- Florentine Kitchen Knives (ESP)

- Fontenille Pataud (FRA)

- Friedr Herder (DEU)

- J Adams (GBR)

- John Nowill & Son (GBR)

- K Sabatier (FRA)

- Pallares (ESP)

- Roland Lannier (FRA)

- Rolin Knives (USA)

- Silverthorn (USA)

- Steelport Knife Co. (USA)

- Windmühlenmesser (DEU)

- Zirh (TUR)

-

Pocket | Outdoor

- A Wright & Son (GBR)

- Andersson & Copra (SWE)

- Au Sabot Folders (FRA)

- Benchmade (USA)

- Buck Knives (USA)

- David Margrita (FRA)

- Friedr Herder (DEU)

- Fontenille Pataud (FRA)

- Helle (NOR)

- Higonokami

- Hults Bruk Axes (SWE)

- Ibberson (GBR)

- Joseph Rogers & Sons (GBR)

- Kalthoff Axes (SWE)

- MOKI Knives (JPN)

- Morakniv (SWE)

- Opinel (FRA)

- Pallares (ESP)

- Tactile Knife Company (USA)

- Wood Tools (GBR)

- Vintage & New Vintage

-

Styles

- Bernal Cutlery Collaborations

- Knife Sets

- Carving Forks | Knives | Sets

- Japanese Kitchen Knives

- Western Kitchen Knives

- Chinese Style Cleavers

- Bread

- Butchery

- Cheese | Charcuterie

- Pocket | Folding

- Woodworking | Hobby | Craft

- Kamisori Razors

- Table | Steak

- Fixed Blades | Axes | Outdoor Tools

- Scissors | Shears | Snips

- Left Handed

- The Vault

- Vintage

- Sharpening

- Kitchen | Cookware

- Tableware | Service

- Pantry

- Accessories

- Deals

- Gift Cards

- INFO

or

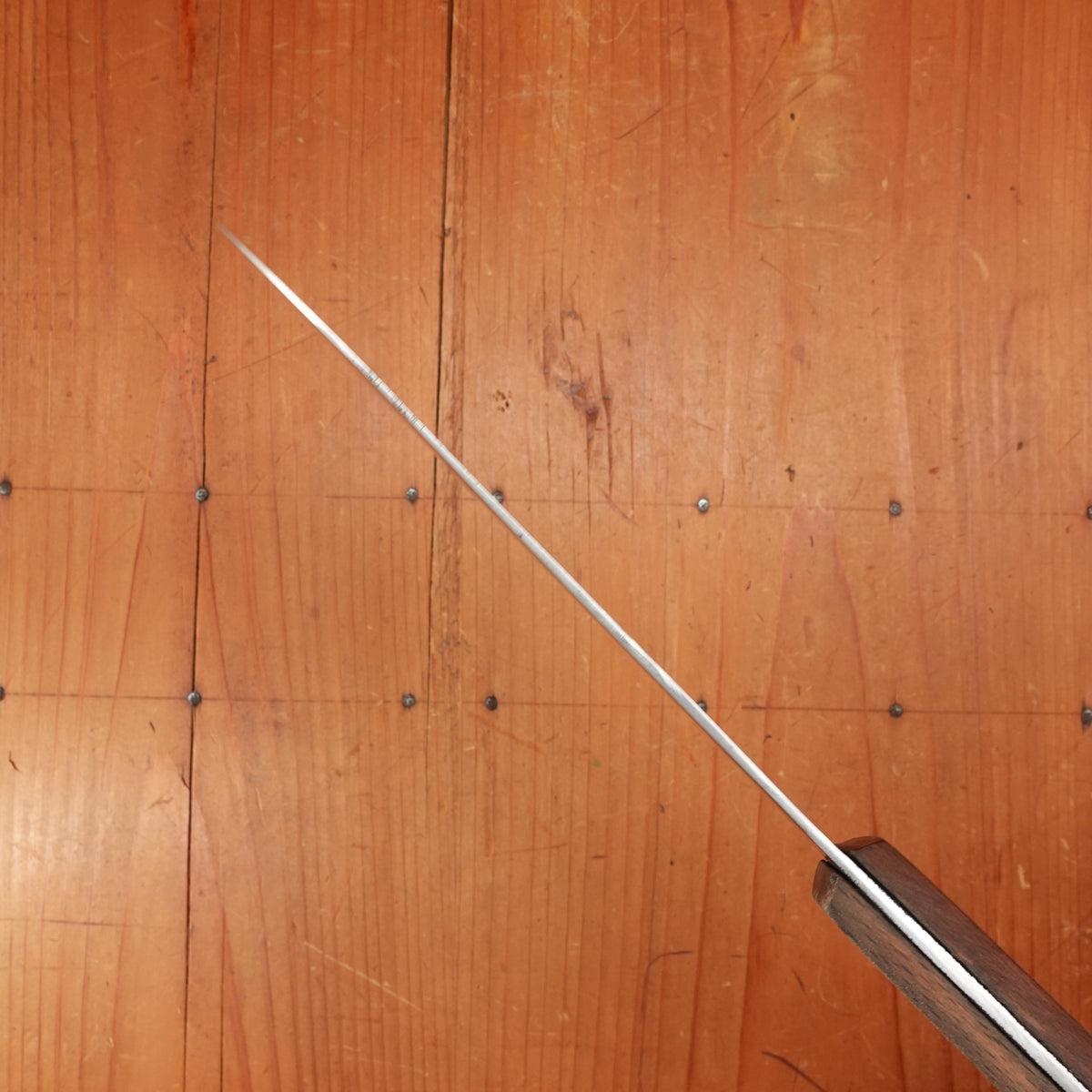

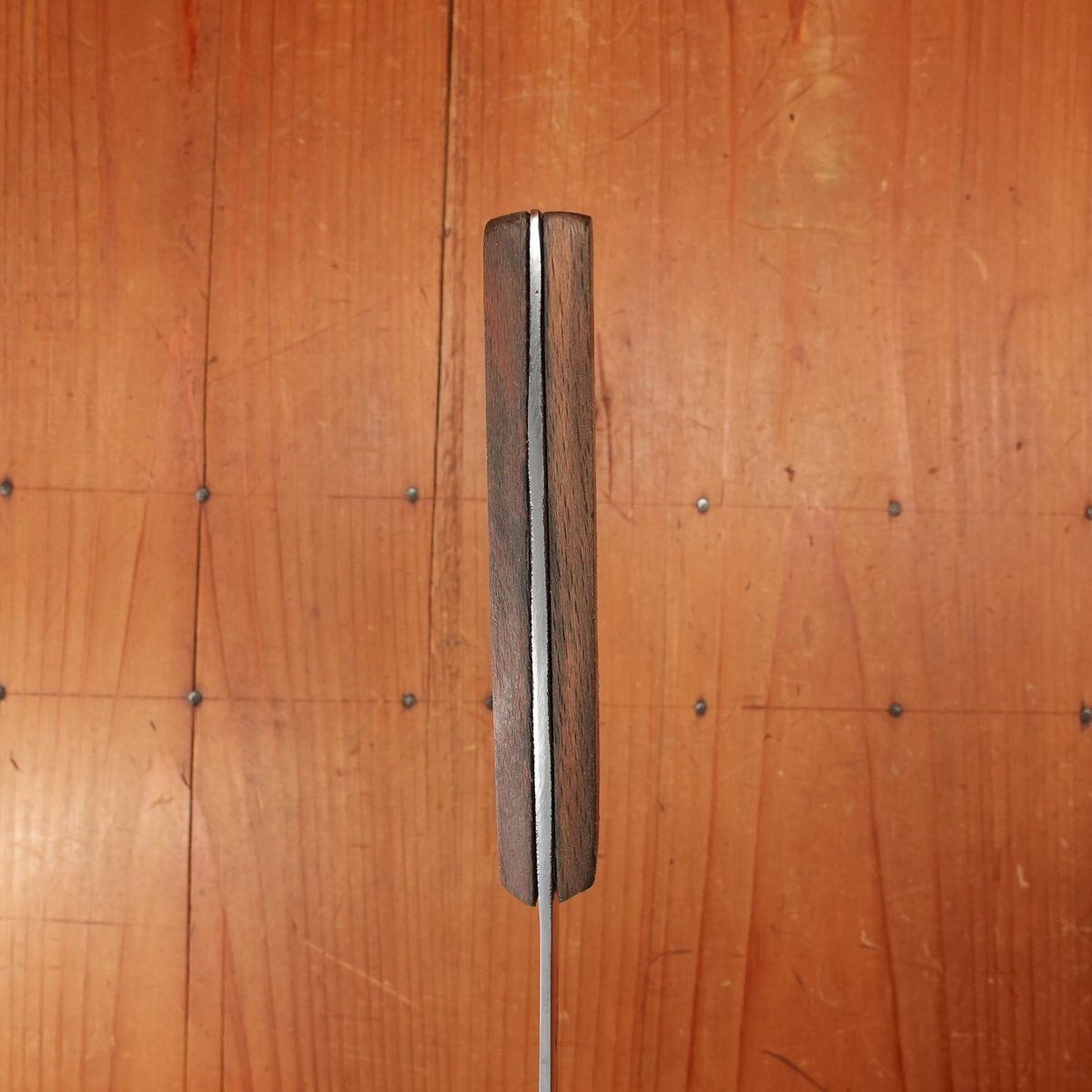

I Wilson 6" Skinning Knife Shear Steel Carbon Steel & Beechwood Sheffield 1890-1920s

-

Regular Price

-

$98.00

-

Sale Price

-

$98.00

-

Regular Price

-

Sale

Sold Out

-

Unit Price

- /per

- Regular Price

- $98.00

- Sale Price

- $98.00

- Regular Price

- Unit Price

- /per

Antique I Wilson skinning knife made in Sheffield England in the late 19th or early 20th century. I Wilson was in operation for a long period of time (1750-1970) but was especially a huge producer of butcher knives in the 19th and early 20th century, the bulk of which were exported to the USA. I Wilson knives are hand forged carbon steel with a 3/4 tang and simple pinned beechwood handle. These were made to be inexpensive but with a good quality steel and gave domestic producers in the USA a run for their money.

Shear steel was a 19th and early 20th century steel that was made by case hardening bars of iron in ceramic boxes packed with charcoal, large numbers of these were heated for days on end at high temperatures and the resulting bars were broken up (it would break or shear rather than bend once carbon added hence 'shear' steel) and forged welded into a larger mass. Shear steel has a very bitey, long lived edge and was one of the top steels in the 19th century western knife making.

This knife has been re-ground and thinned behind the edge on a large 3 foot diameter Japanese water stone wheel (kaiten mizu toishi) and then resurfaced with a medium fine finish, our take on an old style grinding and finishing technique. While the particular wheel used to refurbish this knife is typically used in Japanese knife making it is very similar to the old grinding wheels used to shape European and American hand ground cutlery. A convex face to a blade greatly increases a knife's performance as there is less sticking as there is on a flat face and the blade does not get thick behind the edge nearly as fast as with a flat faced blade. Being that we are often working with old blades that need re-shaping and might have been rusted expect some minor imperfections, we try to give a fresh start to our re-ground blades with an eye towards their original grind style and keeping as much metal is needed on a blade when ever possible.

Recently Viewed

About Bernal Cutlery

We are a full-service cutlery shop offering sharpening services, Japanese and Western culinary knives, vintage knives, outdoor, pocket and craft knives, cooking tools and accessories. We also offer knife skills and sharpening classes, and more.

We are proud to serve kitchen professionals, knife enthusiasts and home cooks alike. Located in the Mission District of San Francisco, California.

766 Valencia Street, SF, CA 94110

1 Ferry Building, Ste. 26, SF, CA 94110