-

Langue

-

Devise

-

NEW

- All New Products

- New Kitchen Knives

- New Kitchen Tools

- Latest Vintage

- New Pocket & Outdoor

- New Pantry

-

What's in my Basket Series

- Nite Yun - Lunette

- Scott & Frost Clark - Dad's Luncheonette, Chef & Author

- Angela Wilson - Avedano's

- Susan Kim - Eat Doshi

- Seth Stowaway - Osito

- Dr. Harold McGee - Author

- Ryo Sakai -Kuma Sushi

- Ian McNemar - Woodworker, Instructor

- Anna Voloshyna - Author

- Jorge Martinex Lillard - Lolo´

- Chris Yang - Piglet & Co

- Griffin Wilson - @cabincorn

- Gabe Rudolph - Gestura Utensils

- Molly DeCoudreaux - Food Photographer

- Geoff Davis - Burdell Soul Food

- Jen and Wes - @crazythickasians

- Josh Donald - Bernal Cutlery

- Kelly Kozak - Bernal Cutlery

- Jessica Sullivan - Poppy SF

- Sylvan Mishima Brackett - Rintaro

- Michael Myers - Film Character

- Ali Hooke - @alihooke

- Bruce Hill - The Chef's Press

- Dylan Carasco - Butcher's Guide

- Spencer Horowitz - Hadeem

-

Japanese Knives

- Ashi Hamono

- Gihei Knives

- Godo Tadaharu

- Hatsukokoro

- Hitohira

- Iwasaki Kamisori

- Kaji-Bei

- Kamo Shiro

- Kanehide

- Konosuke

- MAC Knife

- Masakane

- Makoto Tadokoro Marushin

- Morihei

- Myojin Riki Sesakusho

- Nakagawa Hamono

- Naozumi

- Nigara Hamono

- Sakai Kikumori

- Shigefusa

- Tagai

- Takada no Hamono

- Tanabe Tatara

- Tosa

- Tsukasa Hinoura

- Yoshikane

- Yoshikazu Tanaka

- Wakui

-

Global Knives

- Allday Goods (GBR)

- Alma Knife Co. (USA)

- Astral Works (USA)

- Au Sabot (FRA)

- AZ Knives (ARG)

- Benchmade Cutlery (USA)

- Bernal Cutlery (USA)

- Blenheim Forge (GBR)

- Chazeau Honoré (FRA)

- Dexter Russell (USA)

- Eichenlaub Tableware (DEU)

- Florentine Kitchen Knives (ESP)

- Fontenille Pataud (FRA)

- Friedr Herder (DEU)

- J Adams (GBR)

- John Nowill & Son (GBR)

- K Sabatier (FRA)

- Pallares (ESP)

- Roland Lannier (FRA)

- Rolin Knives (USA)

- Silverthorn (USA)

- Steelport Knife Co. (USA)

- Windmühlenmesser (DEU)

- Zirh (TUR)

-

Pocket | Outdoor

- A Wright & Son (GBR)

- Au Sabot Folders (FRA)

- Benchmade (USA)

- Buck Knives (USA)

- David Margrita (FRA)

- Friedr Herder (DEU)

- Fontenille Pataud (FRA)

- Helle (NOR)

- Higonokami

- Hults Bruk Axes (SWE)

- Ibberson (GBR)

- Joseph Rogers & Sons (GBR)

- Kalthoff Axes (SWE)

- MOKI Knives (JPN)

- Morakniv (SWE)

- Opinel (FRA)

- Pallares (ESP)

- Tactile Knife Company (USA)

- Wood Tools (GBR)

- Vintage & New Vintage

-

Styles

- Bernal Cutlery Collaborations

- Knife Sets

- Carving Forks | Knives | Sets

- Japanese Kitchen Knives

- Western Kitchen Knives

- Chinese Style Cleavers

- Bread

- Butchery

- Cheese | Charcuterie

- Pocket | Folding

- Woodworking | Hobby | Craft

- Kamisori Razors

- Table | Steak

- Fixed Blades | Axes | Outdoor Tools

- Scissors | Shears | Snips

- Left Handed

- The Vault

- Vintage

- Sharpening

- Kitchen | Cookware

- Tableware | Service

- Pantry

- Accessories

- Deals

- Gift Cards

- INFO

ou

Sentan 170mm Chinese Cleaver Stainless Clad Shirogami 2 Kurouchi

-

Prix ordinaire

-

$176.66

-

Prix soldé

-

$176.66

-

Prix ordinaire

-

SOLDES

Épuisé

-

Prix unitaire

- /par

- Prix ordinaire

- $176.66

- Prix soldé

- $176.66

- Prix ordinaire

- Prix unitaire

- /par

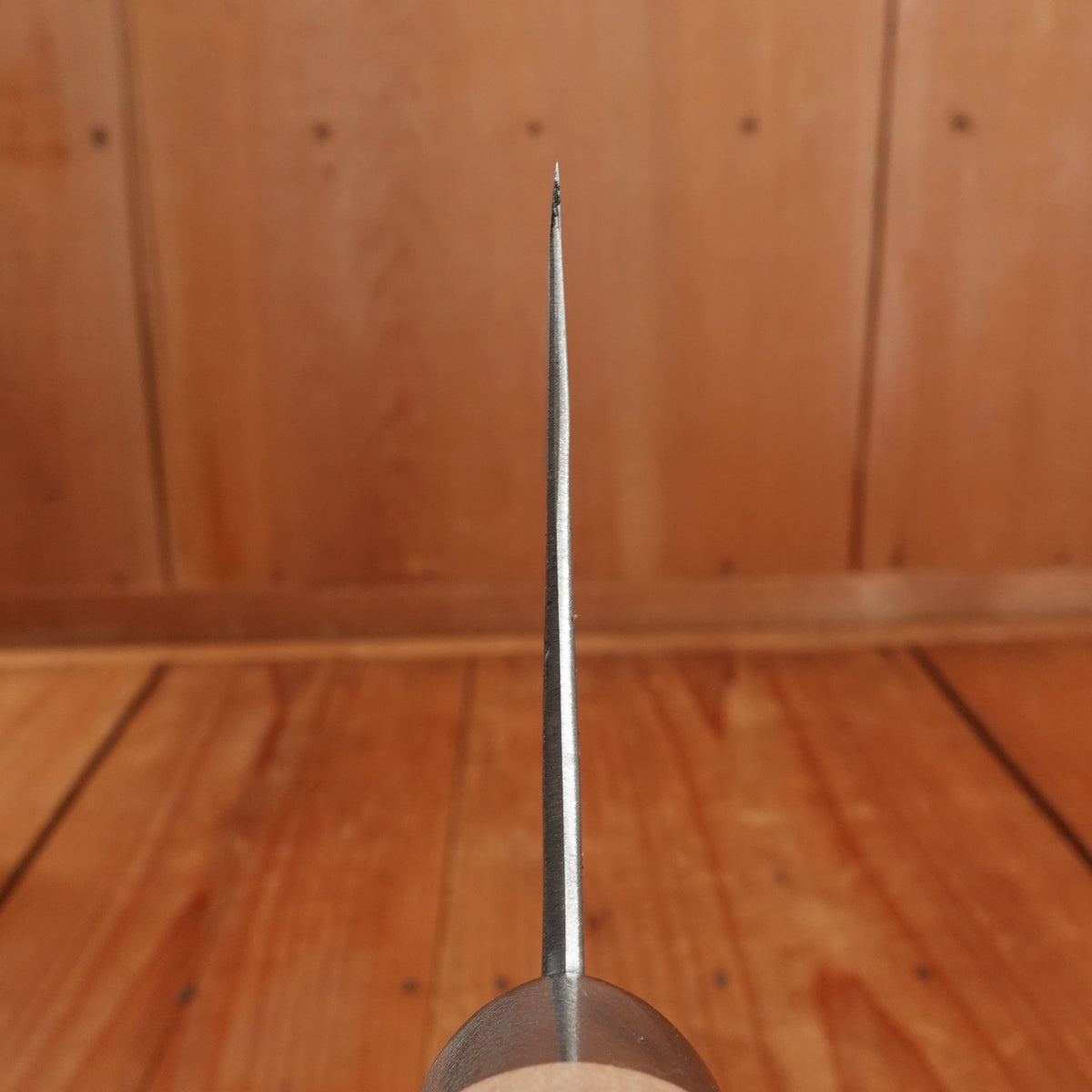

Hatsukokoro Sentan stainless clad shirogami 2 170mm Chinese cleaver.

These are a blend of the best of both high performance Japanese steel and classic time tested Chinese cleaver design. Made for Hatsukokuro in China by a knifemaker specialized in forging traditional Chinese cleavers, these have the feel of a middle weight vegetable and light butchery cleaver, great for vegetables, boneless proteins and if the user is skilled for use in light butchery work where only joints will be cut. The steel in the core of the blade is harder than the average Chinese cleaver and cannot handle hitting hard bones or shellfish shells. It will hold its edge longer and take a finer edge.

Brand: Sentan

Producing Area: China

Profile: Chinese Cleaver

Size: 170mm

Blade Type: Stainless Clad Carbon

Steel Type: Shirogami 2

Handle: WoodTotal Length: 276mm

Handle Length: 115mm

Handle to Tip Length: 171mm

Blade Height: 72mm

Edge Length: 170mm

Thickness: 3.4mm

Weight: 242g

Hand Orientation: Ambidextrous

Saya: Hitohira 250mm Edge Guard Ho Wood

HRC: 61/62

*Approx dimensions from random sample

This is a carbon steel knife. Carbon steel is expected to develop a dark patina with use. It needs to be hand washed and dried immediately after use. Do not air dry. Do not put it in the dishwasher. Long exposure to moisture and debris will result in rust. Any rust development should be removed with a light abrasive.

Twisting, scraping, and heavy use, as well as use on hard and very dense objects can lead to edge damage. Use on a quality wooden cutting board will help the knife stay sharper for longer. Use on hard surfaces like plates and bamboo will reduce the edge life and can result in edge damage.

We recommend hand sharpening on whetstones. We have found that most Japanese knives perform best at a finer finish starting around 4000. Avoid pull through sharpeners and non-water cooled mechanized sharpening. Ceramic honing rods are preferred.

Recently Viewed

About Bernal Cutlery

We are a full-service cutlery shop offering sharpening services, Japanese and Western culinary knives, vintage knives, outdoor, pocket and craft knives, cooking tools and accessories. We also offer knife skills and sharpening classes, and more.

We are proud to serve kitchen professionals, knife enthusiasts and home cooks alike. Located in the Mission District of San Francisco, California.

766 Valencia Street, SF, CA 94110

1 Ferry Building, Ste. 26, SF, CA 94110